Applications

Refining and Chemical Applications

- Turbo Expander Gas Outlet

- CO Boiler Gas Inlet

- CO Boiler Gas Outlet

- Electrostatic Precipitator Gas Inlet

- Electrostatic Precipitator Gas Outlet

- Selective Catalytic Reduction (SCR) Gas Inlet

- ID Fan Gas Inlet

- ID Fan Gas Outlet

- Scrubber Gas Inlet

- Scrubber Gas Outlet

- Scrubber Recirculation Pump Inlet

- Scrubber Recirculation Pump Outlet

- Flare Header Gas Outlet

- Flare Header Gas Inlet

- Reformer Tube Seal

- Coker Tube Seal

- Convection Section Inlet Piping Tube Seals

A turbo-expander is a centrifugal or axial flow turbine through which a high pressure gas is converted into usable power to drive compressors or generators in Fluid Catalytic Cracking Service.

Design Considerations

- Since temperatures are well above flue gas dew point during continuous system operation, the system will be dry and chemical barriers are not necessary

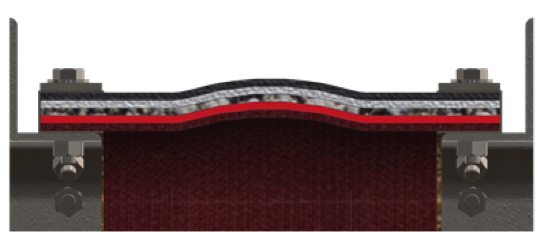

- Composite design and pillow recommended to eliminate the possibility of mechanical damage due to flutter

Expansion joint Specifications

- Temperature: 700F to 900F, Excursions to 1200F

- Media: Hot flue gas

- Particulate: catalyst carryover from the FCC unit

- Operation: System usually on line for 12-18 months

- Pressure: Positive 10″ to 25″ water column

- Movements: High temperatures will generate moderate compressive and lateral movements

- Insulation/Lagging: Do not lag over expansion joint. Remove lagging from flanges to allow radiant cooling

- Expansion joint Recommendation: High temperature expansion joint – Holz Series 1000HTF should be used.

The CO Boiler is where the carbon monoxide in the flue gas is burned as fuel to provide steam for use in the refinery.

Design Considerations

- Since temperatures are well above flue gas dew point during continuous system operation, the system will be dry and chemical barriers are not necessary

- Composite design and pillow recommended to eliminate the possibility of mechanical damage due to flutter

- The design should inhibit direct impingement of the catalyst that will be present

Expansion joint Specifications

- Temperature: 700F to 900F, Excursions to 1200F

- Media: Hot flue gas

- Particulate: catalyst carryover from the FCC unit

- Operation: System usually on line for 12-18 months

- Pressure: Positive 10″ to 25″ water column

- Movements: High temperatures will generate moderate compressive movements

- Insulation/Lagging: Do not lag over expansion joint. Remove lagging from flanges to allow radiant cooling

- Expansion joint Recommendation: High temperature expansion joint – Holz Series 1000HTF should be used

Design Considerations

- Since temperatures are well above flue gas dew point during continuous system operation, the system will be dry and chemical barriers are not needed

- Composite design and pillow recommended to eliminate the possibility of mechanical damage due to flutter

- The design should inhibit direct impingement of the catalyst that will be present

Expansion joint Specifications

- Temperature: 700F to 900F, Excursions to 1200F

- Media: Hot flue gas

- Particulate: catalyst carryover from the FCC unit

- Operation: System usually on line for 12-18 months

- Pressure: Positive 40″ to 50″ water column

- Movements: High temperature will generate moderate compressive movements

- Insulation/Lagging: Do not lag over expansion joint. Remove lagging from flanges to allow radiant cooling

- Expansion joint Recommendation: High temperature expansion joint – Holz Series 1000HTF should be used.

In a refinery operation the Electrostatic Precipitator collects the catalyst from the fluidized bed catalytic cracker unit.

Design Considerations

- A composite should be used

- Flow liner is required, if breach opening exceeds 12″ a double overlapping flow liner should be used

- Use of a pillow will inhibit direct impingement of the particulate that will be present

Expansion joint Specifications

- Temperature: 650F to 800F, Excursions to 1000F

- Media: Hot flue gas

- Particulate: catalyst carryover from the FCC unit

- Operation: Long duration between outages, typically 18 months

- Pressure: Positive 40″ to 50″ Water Column

- Movements: Large lateral and compressive movements due to high temperature

- Insulation/Lagging: Do not lag over expansion joint. Remove lagging from flanges to allow radiant cooling

- Expansion joint Recommendation: High temperature expansion joint – Holz Series 1000HTF or 800HTF should be used

Design Considerations

- Must consider the possibility of dew point (wet condition). A PTFE gas barrier can be added for increased chemical resistance

- Flow liner required when using a PTFE product

Expansion joint Specifications

- Temperature: 350F to 500F, Excursions to 600F

- Media: Flue gas from precipitator

- Particulate: Minimal

- Operation: Dew point could present potential corrosion problems

- Pressure: Ranges from slightly negative to slightly positive, -5″ to +5″ water column

- Movements: Moderate compressive and lateral movements expected

- Insulation/Lagging: Temperatures allow lagging

- Expansion joint Recommendation: High temperature expansion joint – Holz Series 600HTF or PTFE should be used

Selective Catalytic Reducers are pollution control devices used to reduce Nitrogen Oxide emissions that are present in the exhaust of furnaces and reactors.

Design Considerations

- A composite should be used

- Since temperatures are above flue gas dew point, the system will be dry during continuous operation; However, changes in system operation or frequent outages can cause wet, corrosive conditions and an optional chemical barrier should be considered

Expansion joint Specifications

- Temperature: 350F to 750F

- Media: flue gas containing nitrogen oxide

- Particulate: Moderate

- Pressure: Pressure ranges from -20″ to +20″ water column

- Movements: Moderate movements expected

- Expansion joint Recommendation: High temperature expansion joint – Holz Series 800HTF or 600HTF should be used

Induced Draft fans are used to help draw the flue gas through the ductwork and out of the stack

Design Considerations

- Many induced draft fans utilize small dual inlets with control or shutoff dampers. Designs must not interfere with damper blades

- Flow liner is required when using a composite

Expansion joint Specifications

- Temperature: 300F to 500F

- Media: Flue gas from Precipitator

- Particulate: Minimal

- Operation: Although movements are not severe temperatures will approach dew point and present potential corrosion problems

- Pressure: Slightly negative, -15″ water column

- Movements: Minimal movement, primarily vibration

- Expansion joint Recommendation: Depending on conditions a E14GGN, V14GGN, or 600HTF can be used

Design Considerations

- Many induced draft fans utilize small dual inlets with control or shutoff dampers. Designs must not interfere with damper blades

- Flow liner is required when using a composite

Expansion joint Specifications

- Temperature: 300F to 500F

- Media: Flue gas from Precipitator

- Particulate: Minimal

- Operation: Although movements are not severe temperatures will approach dew point and present potential corrosion problems

- Pressure: Slightly negative, -15″ water column

- Movements: Minimal movement, primarily vibration

- Expansion joint Recommendation: Depending on conditions a E14GGN, V14GGN, or 600HTF can be used

A scrubber is an air pollution control device used to remove sulfur dioxide from the flue gas

Design Considerations

- Expansion joint may see more flexing than in other applications, good flexibility is needed

- Flow liner is required when using a PTFE

Expansion joint Specifications

- Temperature: 280F-400F

- Media: Flue Gas

- Particulate: Minimal

- Operation: Temperatures will approach dew point and present potential corrosion problems

- Pressure: Positive 35″ to 55″ water column

- Movements: small movements expected

- Insulation/Lagging: Low temperatures allow lagging

- Expansion joint Recommendation: Depending on scrubber configuration, use a flue duct expansion joint – Holz Series 945 or a high temperature expansion joint should be used

Design Considerations

- Partially open bypass dampers or changes in direction of ductwork may create excessive gas stream turbulence resulting in direct flue gas impingement

Expansion joint Specifications

- Temperature: 200F-350F

- Media: Wet scrubbed flue gas

- Particulate: Negligible

- Operation: Temperatures will approach dew point and present potential corrosion problems

- Pressure: Ranges from slightly negative to slightly positive, -15″ to +15″ water column

- Movements: Minimal movement

- Insulation/Lagging: Low temperatures allow lagging

- Expansion joint Recommendation: Depending on scrubber configuration, use a flue duct expansion joint – Holz Series 945 or a high temperature expansion joint should be used

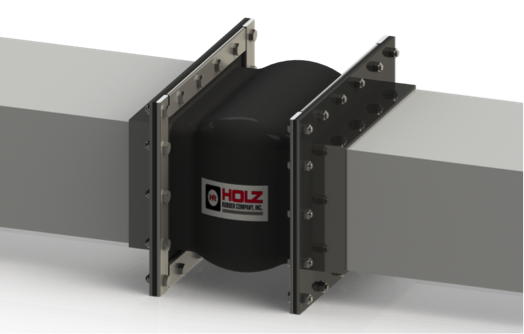

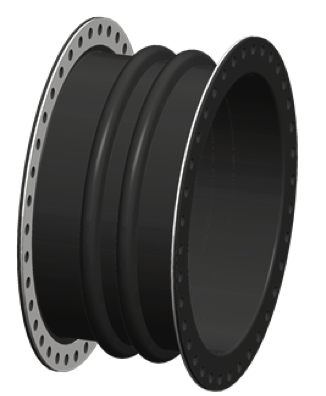

A recirculation pump moves some of the spent scrubbing liquid back into the scrubber where it is recycled and the remainder is sent to a treatment system.

Design Considerations

- Internal metal flow liner is recommended due to abrasive environment

- Filled arch expansion joints are used to prevent scrubber liquid arch caking

Expansion joint Specifications

- Temperature: 100F to 180F

- Media: Spent scrubbing liquid

- Particulate: Moderate

- Pressure: Negative, 25″ HG

- Movements: Moderate movements

- Expansion joint Recommendation: Holz 320 style or 320-2 double arch

Design Considerations

- Internal metal flow liner is recommended

- Filled arch expansion joints are used to prevent scrubber liquid arch caking.

Expansion joint Specifications

- Temperature: 100F to 180F

- Media: Spent scrubbing liquid

- Particulate: Moderate

- Pressure: 80 PSI

- Movements: Moderate movements

- Expansion joint Recommendation: Holz 320 style or 320-2 double arch

Expansion joints are used in flare headers as an alternative to piping expansion loops

Design Considerations

- Expansion joint materials must be compatible with hydrocarbon gases

- Possible damper interference

Expansion joint Specifications

- Temperature: 180F to 300F

- Media: hydrocarbon gases

- Particulate: minimal, particles less than 300um

- Pressure: 2 to 5 psi

- Movements: Moderate

- Expansion joint Recommendation: Holz 945 style

Design Considerations

- Expansion joint materials must be compatible with hydrocarbon gases

- Possible damper interference

Expansion joint Specifications

- Temperature: 180F to 300F

- Media: hydrocarbon gases

- Particulate: minimal, particles less than 300um

- Pressure: 2 to 5 psi

- Movements: Moderate

- Expansion joint Recommendation: Holz 945 style

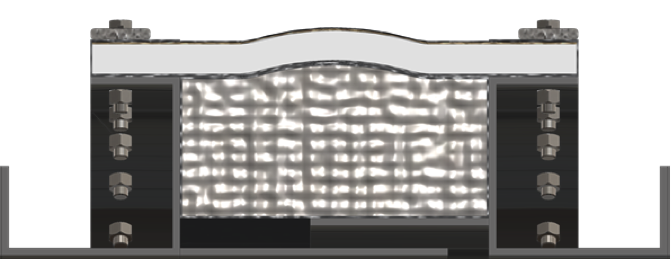

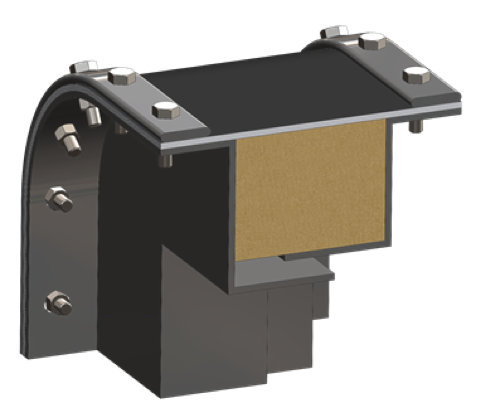

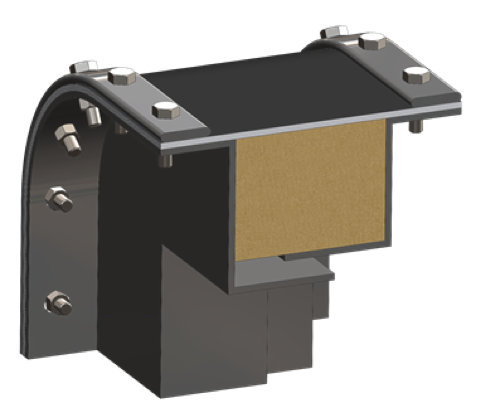

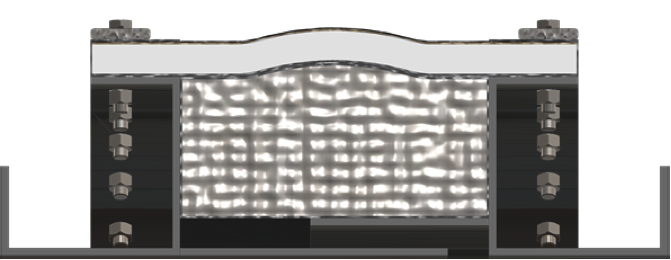

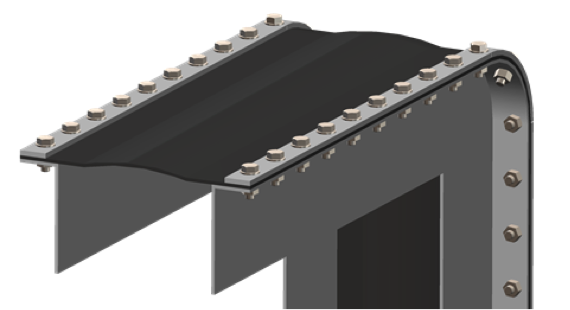

The openings around the steam reformers allow air to be drawn out of the heater which is costly. Reformer tube seals are used to stop the ingress of cold air while absorbing large axial movements.

Design Considerations

- Holz uses a special high grade silica fabric that stays extremely flexible to its rated temperature

- 2″ flat on each end for easier clamp installation

Tube Seal Specifications

- Temperature: 1500F to 1850F

- Media: Hot Air

- Particulate: Minimal

- Pressure: 0 to 1 psi

- Movements: Depending on installer up to 8″ of extension

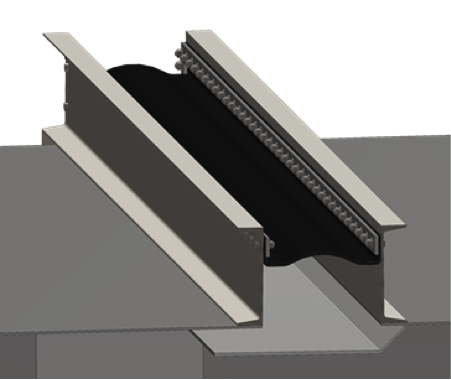

Design Considerations

- 2″ flats on ends of seal for easier clamp installation

Tube Seal Specifications

- Temperature: 1000F to 1300F

- Media: Air from Coker heaters

- Particulate: Minimal

- Pressure: 0 to 1 psi

- Movements: Depending on installation up to 3″ of extension

Design Considerations

- 2″ flats on ends of seal for easier clamp installation

Tube Seal Specifications

- Temperature: 1000F to 1300F

- Media: Hot air

- Particulate: Minimal

- Pressure: 0 to 1 psi

- Movements: Depending on installation up to 3″ of extension